We are a Commercial Group having Diverse & Multiple Business Interests in Various Commercial Segments speard across a wide geographical area. Our Strength are our people who have more than a decade’s experience , as a minimum , in the fields they specialise in.

Our products

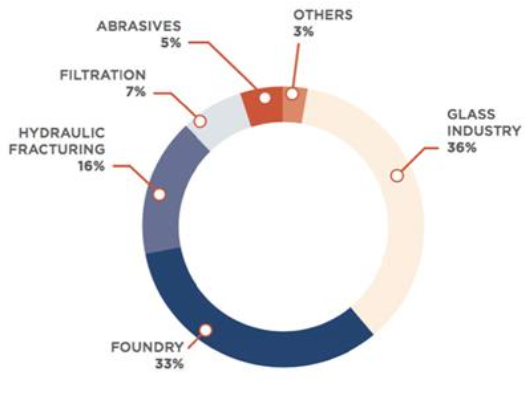

SILICA GRAVEL , SILICA SAND , SILICA POWDER , SILICA LUMPS SILICA QUARTZ CALCIUM CARBONATE, FELDSPARS

We provide the highest purity silica gravel and silica sand products to buyers around the world for a variety of industrial purposes. Our high pure silica can be purchased in particle sizes ranging from less than 100 micron, 100 micron to 900 micron also 1mm to 5mm sizes. Also we have silica gravel for all range of sizes from 3 mm to 40 mm. Our silica is mined from south east of Riyadh region, Saudi Arabia and is processed in our plant in nearby Riyadh. We can provide pure silica as both washed and dry.

We also provide high purity calcium carbonate and feldspars to meet any industrial demand. Our crushed limestone can be produced at any desired particle size

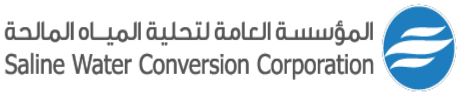

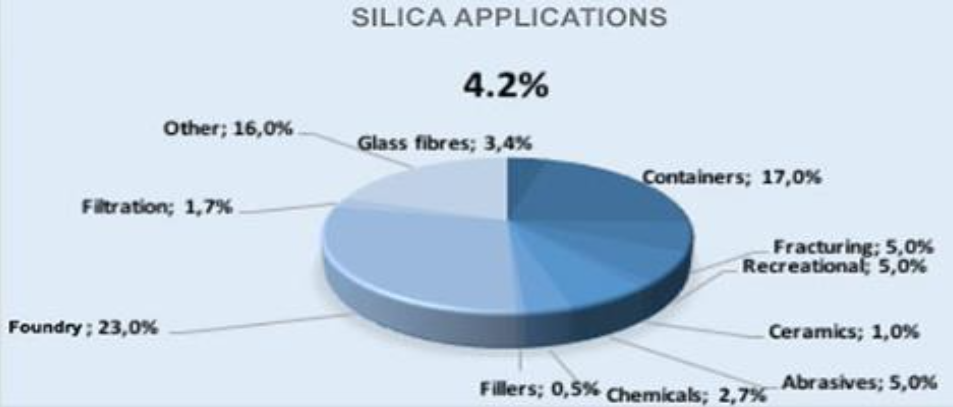

USES IN & AS :

- As PROPPANT / FRAC SAND : In ‘Plug & Perf Methods’ in Oil & Gas Industry in Oil & Gas Recovery Processes in Fracing or Hydraulic Fratcuring or Hydrofracking. Silica Sand is pumped down holes in deep well applications to prop open rock fissures and increase the flow rate of natural gas or oil. In this specialized application, round, whole grain deposits are used to maximize permeability and prevent formation cuttings from entering the well bore. Silica’s hardness and its overall structural integrity combine to deliver the required crush resistance of the high pressures present in wells up to 2,450 metres deep. Its chemical purity is required to resist chemical attack in corrosive environments.

- MAIN COMPONENT OF GLASS-MAKING: Pulverised & Ground Silica Sand is the basic ingredient in all sort of standard & specialty Glass Making: Glass for Building & Automotive Use; Container Glass for Food & Beverages; Tableware; Fiberglass Insulation; Reinforced Fiberglass; Test Tube & Other Scientic Tools; Incandescent & Fluorescent Lamps; TV & Computer CRT Monitors;

- METAL CASTING : In Ferrous & Non-Ferrous Foundries. Cores & Moulds.

- METAL PRODUCTION : As FLUX In production of Ferrous & Non-Ferrous both metals. Lump Silica is used alone of in conjunction with Limestone, to refine & purify & add strength & Corrosion Resistance.

- CHEMICAL PRODUCTION : Industrial Sand is the main component in producing Sodium Silicate , Sodium Tetrachloride , & Silicone Gels which are used to produce Household & Industrial Cleaners , manufacture Fiber Optics , and to Purify Cooking Oils & Brewed Beverages. Silicon-based chemicals are the foundation of thousands of everyday applications ranging from food processing to soap and dye production.

- CONSTRUCTION : Whole grain silica is put to use in flooring compounds, mortars, specialty cements, stucco, roofing shingles, skid resistant surfaces, and asphalt mixtures to provide packing density and flexural strength without adversely affecting the chemical properties of the binding system. Ground silica performs as a functional extender to add durability and anti-corrosion and weathering properties in epoxy-based compounds, sealants, and caulks.

- FILTRATION & WATER TREATMENT : Silica sand is an effective filtration bed in the removal of contaminants in both processing of wastewater and in the filtration of the drinking water. Silica sand neutralizes the acidic elements to maintain optimal pH balance in water filters.As it is chemically inert, it will not react when exposed to acids, contaminants, volatile organics or solvents. Silica Gravel is used as packing material in deep-water wells to increase yield from the aquifer by expanding the permeable zone around the well screen and preventing the infiltration of fine particles from the formation.

- CERAMICS & REFRACTORIES : Ground silica is an essential component of the glaze and body formulations of all types of ceramic products, including tableware, sanitary ware, and floor and wall tile. In the ceramic body, silica is the skeletal structure upon which clays and flux components attach. The SiO2 contribution is used to modify thermal expansion, regulate drying and shrinkage, and improve structural integrity and appearance. Silica products are also used as the primary aggregate in both shape and monolithic type refractories to provide high temperature resistance to acidic attack in industrial furnaces.

- PAINTS & COATINGS : Paint formulators select micron-sized industrial sands to improve the appearance and durability of architectural and industrial paint and coatings. High purity silica contributes critical performance properties such as brightness and reflectance, colour consistency, and oil absorption. In architectural paints, silica fillers improve tint retention, durability, and resistance to dirt, mildew, cracking, and weathering. Low oil absorption allows increased pigment loading for improved finish colour. In marine and maintenance coatings, the durability of silica imparts excellent abrasion and corrosion resistance.

- INDUSTRIAL ABRASIVES : Used as a mineral abrasive for Indstrial Blasting , with PPE used against the dust.

- RECREATIONAL PRODUCTS : Silica sand is used for golf course bunkers and greens as well as the construction of natural or synthetic athletic fields. In golf and sports turf applications, Silica Sand is the structural component of an inert, uncontaminated growing media. also used to repair greens and to facilitate everyday maintenance like root aeration and fertilization. The natural grain shape and controlled particle size distribution of silica provides the required permeability and compaction properties for drainage, healthy plant growth, and stability.

Our Clients: